It seems an oddity. An anomaly. A printer that can print objects rather than on paper? How could that possibly be useful beyond a weekend jaunt at trying to duplicate miscellaneous things lying around the house? And wouldn't it be easier to buy your product in the store rather than to sit around patiently waiting for whatever it is you want, to be ready?

3D printing (also known as additive manufacturing) is still a young industry, which means its effects are hard to predict. But already there are applications that we can think of. Say you're on a base in Antarctica and a vital screw breaks on one of your machines. Spares are limited there and shipping ultra-expensive -- nearly impossible during the long winter. A 3D printer could help solve that problem. But its aims could also benefit those in more ordinary situations.

First, a few words about how additive manufacturing works. As the term implies, "additive" means that you are adding on to something; in this case, building up an object layer by layer. This sort of process is common in nature. Think about layers of sand building up over time, cementing in fossils for dinosaur-hunters to discover millions of years later. Or the slow drip of mineral deposits on a cave floor, which creates stalacmites. (Stalactites are formed through a similar process, but are on the roofs of caves.)

3D printing first took place in the 1990s at the Massachusetts Institute of Technology and a firm called 3D Systems, according to How Stuff Works. There are actually several processes that can create 3D printed objects. We'll just give you a couple of examples below.

One uses conventional inkjets -- the same stuff you find in conventional printers -- that can swivel back and forth and deposit layers of polymers to form into an object. Aother form (called binder 3D printing) brings together two kinds of materials in each layer: a powder (from the inkjet) and a glue. The latter is a bit faster and able to use more kinds of materials, How Stuff Works says.

No matter what kind of additive process you use, generally speaking there is the same procedure to get an object from concept to product, the website continues. You create a 3-D image using computer-assisted software. Then, you convert the image to a standard format that all 3D printers understand, called STL (standard tessellation language), have the machine read it, and after a few setup steps begin printing. Sometimes you'll need to remove powder or make other changes after the object is finished, too.

One large benefit of 3D printing is it often can use materials of different thicknesses within the same process. This can lead to lighter or more precisely manufactured materials than what you would find using other technologies, which is great in manufacturing. Think about engine or machine components. Also, depending on the situation, it can produce materials more cheaply than conventional technologies. A group of dedicated dog-lovers recently created a 3D prosthetic leg for a weiner dog, Hobbes, in part because it was easier than other ways of doing it.

For a large company, it can reduce the cost of creating prototypes -- which will slash research and development costs. The cheap development, according to Stratsys, encourages workers to try out more models of a particular prototype, which is a much more realistic way of testing than a bunch of computer models. For example, you can test how well a part fits with other parts before you go to manufacturing. Or, you can make sure that a device that is supposed to form on to a human, for example -- maybe a pair of glasses -- actually fits.

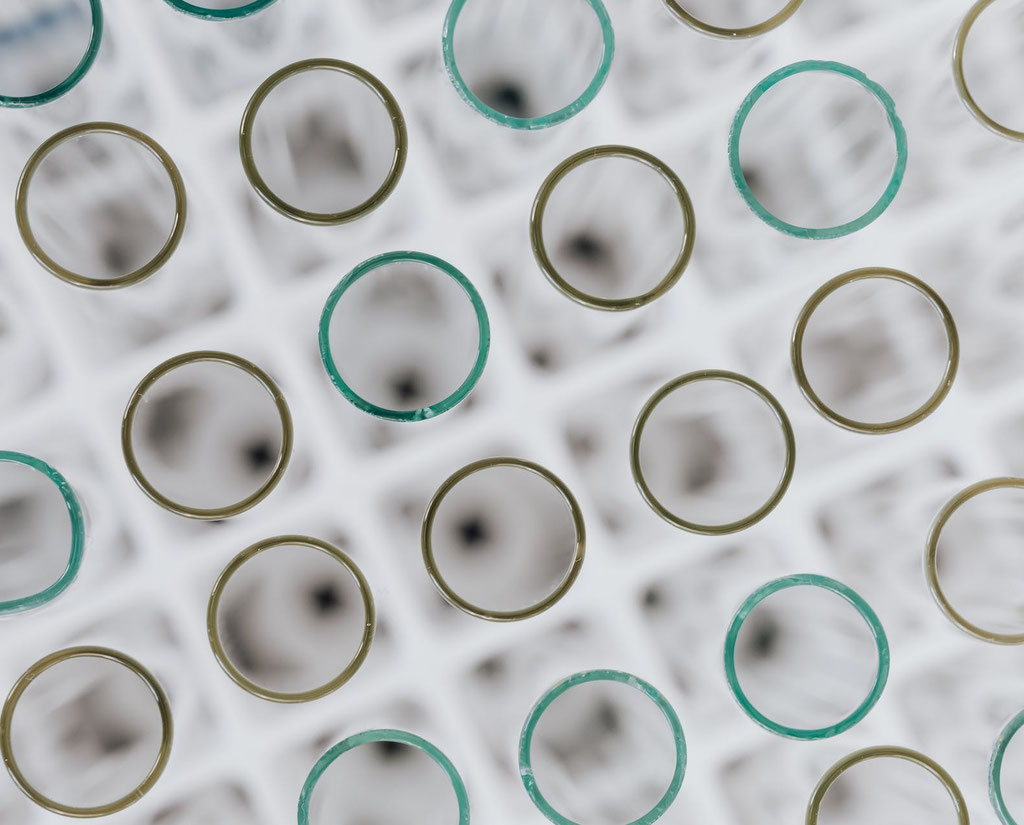

Perhaps the most game-changing aspect is in human health. Imagine a printer that can 3D print a new tooth if you lose one. Or a hearing aid that is more finely molded -- custom-molded, in fact -- to your ear than conventional technology will give you. But in reality, 3D printing applications are only limited by our imaginations. If there's a better way to create something with a 3D printer than with what was available before, you can be sure people will use it.

Top image: Wikimedia Commons