Our company is planning to build/expand a factory focused on producing __________ components. Is this eligible for the prize?

Any questions about component eligibility should refer to Appendix B (page 34) of the official rules. The prize team cannot provide specific feedback about technology types.

Does manufacturing of components for ____________ sector apply for this prize?

Any questions about component eligibility should refer to Appendix B (page 34) of the official rules. The prize team cannot provide specific feedback about technology types.

Is the number of Phase 1 winners based on the number of applicants? Or based on the number of those deemed eligible?

The number of Phase 1 winners will be determined based on the number of meritorious submissions until funds are exhausted, not the number of competitors.

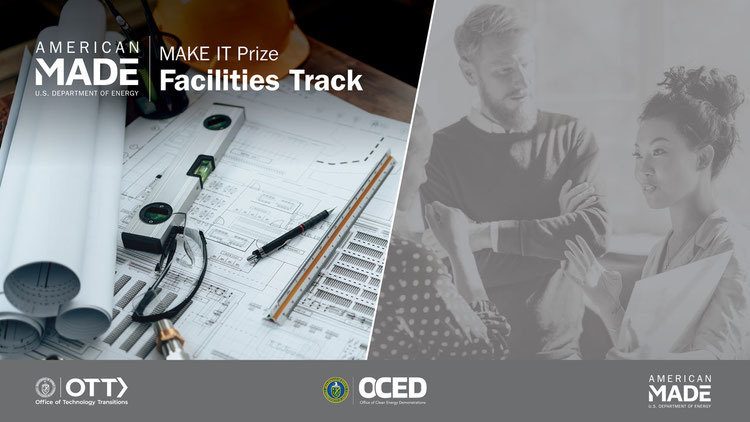

If we are not successful in the Primary timeline, would we be able to submit in the Secondary timeline?

Yes, competitors may submit, but are strongly encouraged to consider the feedback that they receive prior to resubmitting.

Does the Strategies Track follow this same Primary and Secondary timeline?

No. The Strategies Track has a different timeline, please refer to the rules of the Strategy Track.

Is there any benefit to submitting before February 1st for Phase 1 in the Primary Timeline?

Submissions will not be reviewed prior to the submission deadline. However, we do recommend that you submit early to avoid any last-minute technical difficulties.

Is it accurate to say that awards will be rolling, such that money could be running out even while submissions are still coming in?

While a phase is open, no submissions will be reviewed until the deadline has been reached. At that point, it is possible that enough meritorious submissions could receive prize awards resulting in no available funding for the Secondary Timeline.

If your Statement of Intent is rejected in the Primary Timeline, will feedback be given so that an improved submission can be made in the Secondary Timeline?

Yes, feedback will be provided.

If an organization wants to submit multiple entries for different technologies, do we need to create multiple HeroX accounts?

No, you may use the same HeroX account to apply multiple times. As a reminder the technology category must be different for each submission.

How much flexibility is there on specific location of the facility if plans change? Does the application need to be location-specific, if two different states are in the running for strategic reasons?

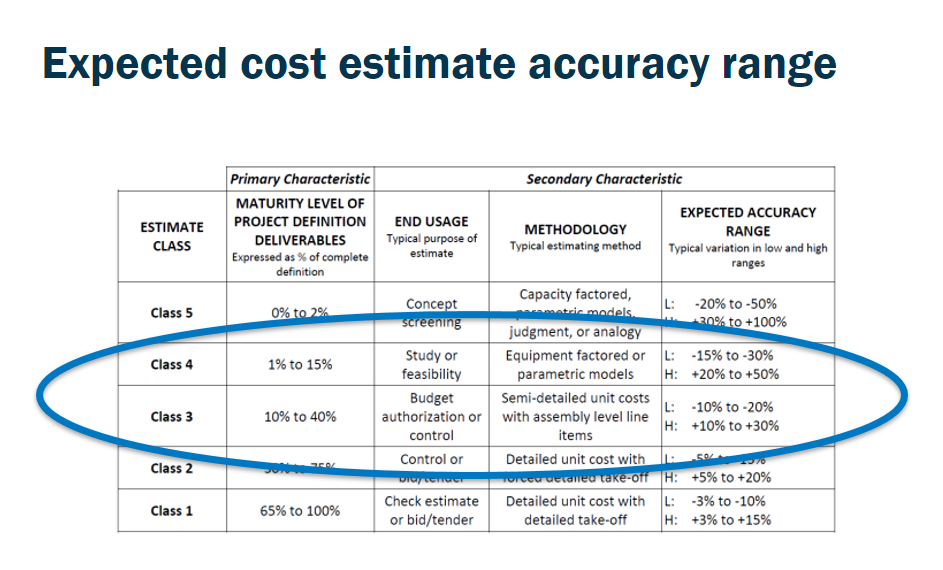

Location of the proposed facility is not requested as part of the Statement of Intent. As part of Phase 1 submission, we ask to list all possible locations being considered for the manufacturing plant. However, additional information must be included for each location, so we advise to include only the shortlist of realistic options under consideration. At the time of Phase 2 submission, one specific location must have been identified and confirmed in order to be able to submit the required documents and information.

What is the expected template/contents of the Statement of Intent?

Please see the official rules document for a list of what needs to be included in the submission and how the submission will be assessed.

Are new pilot manufacturing facilities eligible, assuming the technology component is derisked?

Submissions for pilot manufacturing facilities are eligible, as long as they are related to one of the technology components listed in Appendix B of the prize rules and comply with the other prize requirements. Competitors should keep in mind that RD&D work should not be part of a submission to this prize. Note that the review criteria include the technology’s readiness level, any technology or adoption risks, and impact of the proposed facility (among other factors), and competitors should make clear how their proposed pilot manufacturing line meets these criteria. In particular, competitors should make clear the difference in performance, throughput, and cost between the proposed pilot line and a manufacturing facility at scale for the same component.

What can we spend the Phase 2 money on?

This is a prize competition, with cash prizes awarded for work completed. Competitors may use prize funds in the manner that best suits their organization. No reporting of use of prize funds is required.

When we say brownfield sites, are we trying to find brownfield sites that were used in other energy industry applications? Or any brownfield site?

Any brownfield site is eligible.

When you say financing is in place for shovel-ready, does this mean that the project has to be able to proceed whether or not it wins the prize?

The goal of this prize is to stimulate activity toward building manufacturing facilities on specific technology component with an accelerated timeline according to the prize timeline. This program is meant to give a cash award to facilities that will be shovel-ready by the end of the competition. The prize amount is not sufficient for what is typically expected to build such facilities. We expect competitors be able to secure the funding necessary for construction from a private or public source as part of the competition.

Does having marketing announcements on expansion plans lower chances for getting the prize?

No, however we expect that the competitor will complete most of the work necessary to put together a strong submission within the prize timeline.

Once awarded, when is money distributed to winners, and on what basis?

When teams are notified that they have been selected as winners, instructions will be included for how to receive prize money. The submission form requires teams to list who will be paid if a prize is won. That individual or entity will need to provide a W-9 and banking information. Once that information is received, the payment process can take anywhere from 2-4 weeks.

Is the focus on U.S. manufacturing for supply to the U.S., or are exporters also welcome?

As long as the manufacturing facility is based in the U.S. and the competitor complies with the prize rules, including those related to eligibility, it is fine if exporting the final product is part of the facility’s plan.

Does carbon capture include direct air capture?

Not for this prize. Please refer to Appendix B of the prize rules for additional information.

Can a company be based in the U.S. and in a different country as well?

Please refer to the eligibility criteria listed in the prize rules – including but not limited to section 1.4: “Competitors must be U.S. persons (citizens or resident aliens) or entities incorporated in the United States and maintain a primary place of business in the United States.”

Can an applicant be a U.S.-based division (with work done by U.S. citizens) of a larger company that is based outside the U.S.?

In general, yes. The correct answer will depend on the specific situation. Please refer to the eligibility criteria listed in the prize rules – including but not limited to section 1.4: “Competitors must be U.S. persons (citizens or resident aliens) or entities incorporated in the United States and maintain a primary place of business in the United States.”