Challenge Details

We are inviting innovative and cost effective solution to have an alternative for 2W engines ADC 12 parts which are currently being manufactured by HPDC process.

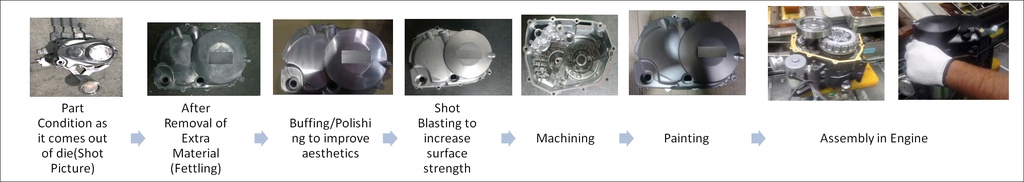

Post Processes for these parts are machining and painting.

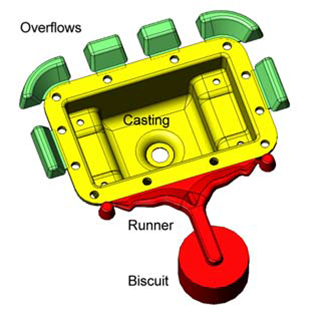

These parts come out of the die with lots of excess material in the form of gate, overflow, chill vents etc, which are necessary to attain the shape as per process limiations.

We are open for alternative process as well as material while fulfilling all requirements as per our final product. The aim would be to attain a cost saving of minimum 20% of our present product cost.

Current Scenario

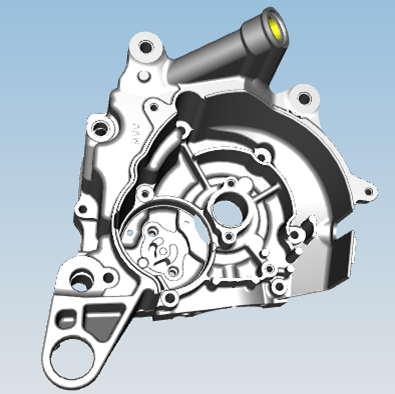

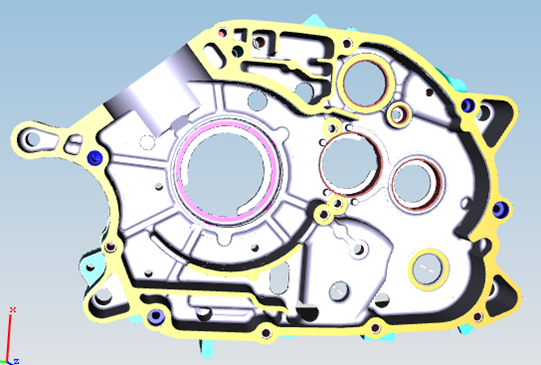

The crank case covers are used for providing an enclosure for the moving parts of a 2W engine. It has channels to carry oil for internal lubrication and also helps to contain the engine temperature. The outer part is also an aesthetic and strength component for the 2 wheeler.

Challenge Overview

Our aim is therefore to obtain a solution which increases the cost effectiveness of HPDC either by

Provided following requirements are met

Other details are mentioned in the guidelines tab.

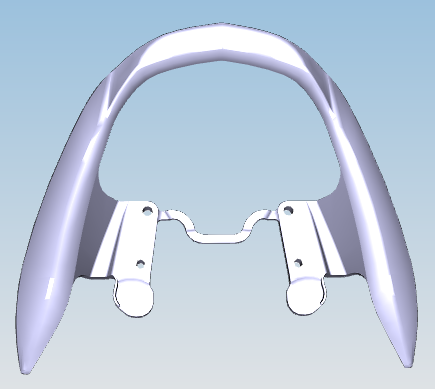

We would recommend solutions which are applicable to a variety of our products, other than crankcase covers. Below are a few examples:

Rear Grip Crank Case Right- Scooter

Crank Case Right- Motorcycle

Registering for Problem

Click "Follow the Challenge" above to be notified of any status updates to the challenge.

Click "Yes Sign Me Up!" above to register for the challenge. You will be notified of any status updates and be able to create an entry to the challenge when it opens.

Leave a comment in our Comments Thread to join the conversation, ask questions or connect with other innovators.

Reward Money

We will be evaluating the solutions at different stages of development and would be eligible for rewards accordingly. Details in guideline tab.

Solution Requirements

In this challenge, solvers need to submit a solution which ensures/enlisits:

Reward Money and Stages

We will be rewarding the solver based on the extent to which he is able to meet our expectations.

Solutions will be rewarded according to the development stages as follows:

If more than one solutions are shortlisted at different stages, then the prize money will be divided equally among all winners.

Data to be shared to Solver

Solver will have access to all part/process related data for our current setting:

•Part Drawing/3D data

•In depth process details

•Testing standards

•Cost details structure

Specific details shall be shared with interested solver based on mutual discussion.

Final Evaluation Criteria

We would award the best solution a prize money of USD 10,000-50,000 as per various challenge stages. The best solution as per our requirement should have:

• Highest cost saving

•Lowest Capital investment

•Technical feasibility as per availability in the market

•Greener Solution

•Wider scope of applicability

Further terms and Conditions

Indicated results would be verified through a prototype development/ feasibility study/Challenger testing protocols and accordingly would be qualified for reward.

Further engagement with the solver can be explored depending on the solution feasibility of expansion in other areas as mentioned in the stage guidelines

Cost heads as per the challenger

RM Cost

1. Raw Material Cost

Conversion Cost

1. Process Cost( HPDC)

2. Fettling Cost

3. Buffing and shot blasting cost ( Finishing)

4. Material melting cost

Others

1. Overhead cost

2. Rejection Cost

3. Packing Cost

4. Freight Charges

5. Inventory Cost