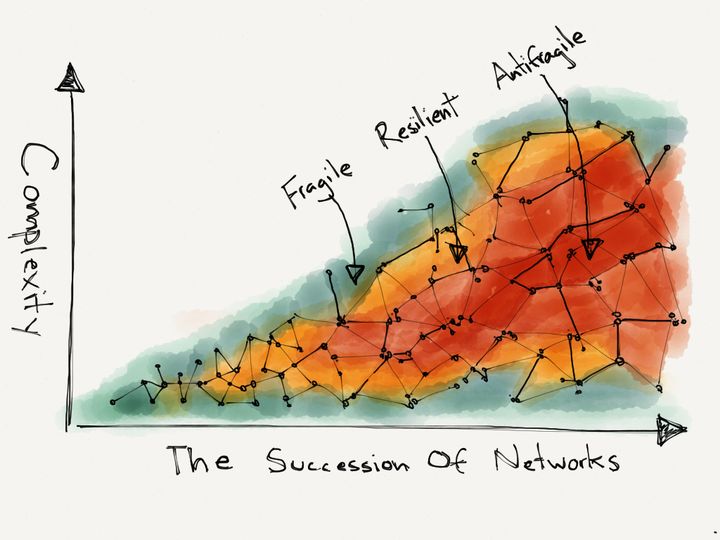

Robots have long been used to carry out tasks, ranging from construction and factory assembling to cleaning and surveying. But robots that can reconfigure themselves or reassemble to perform different tasks - that is the way of the future, it seems. It is what is known as reconfigurable and self-assembling robotics, a part of the wider field of swarm robotics, where robots are capable of assembling themselves into more complex configurations.

This new approach to the coordination of multi-robot systems consist of large numbers of simple robots programmed with collective behavior. This approach emerged as part of the field of artificial swarm intelligence, but also owes a great deal of inspiration from the biological studies of insects, ants and other fields in nature, where swarm behavior occurs.

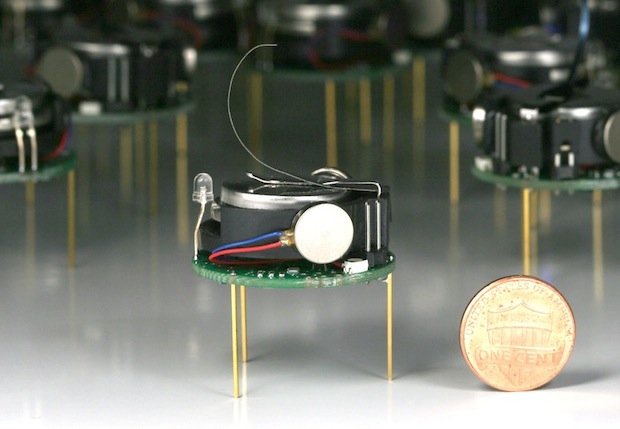

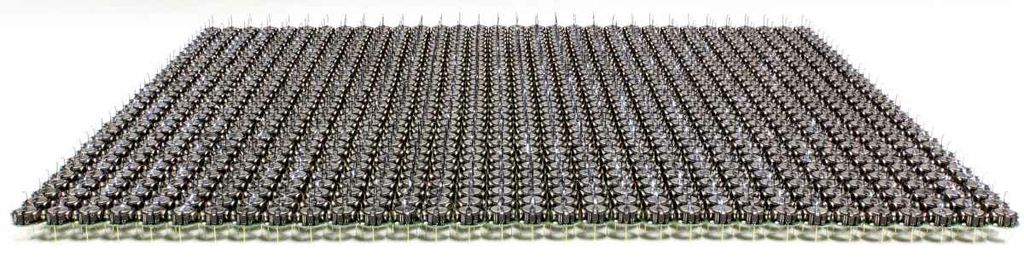

And with every passing year, the field is booming with new and exciting examples of this technology in action. Consider the Kilobots, a concept for self-assembling robots created by Harvard roboticists back in 2011. At the time, they had only made 25 of the robots. By 2013, that number had climbed to 100. And as of this past August, the number of robots assembled reached 1024.

The Kilobots were conceived by Michael Rubenstein, Alejandro Cornejo, and Professor Radhika Nagpal of Harvard’s Self-Organizing Systems Research Group. In a paper published in August in Science, they described their invention. Basically, they are a series of round, little robots that are the same diameter as a quarter, with a metal spring on top and three thin metal legs. Each one moves around by vibrating their legs and communicate with each other via infrared transmitters and receivers.

Swarm Robotics and Harvard's Kilobots

Whereas previous proof-of-concept projects with swarm robotics have involved large-scale computer simulations, but only a handful of physical robots, the Kilobots are the first to actually live up to the name. With 1024 different units, they are able to accomplish the first and most important aspect of swarm robotics, which is simply having enough units so that collective behavior can be accomplished - even if a few units break down or their programming fails.

The second thing intrinsic to swarm robotics is the software and infrastructure needed to manage and control a huge number of robots. With a thousand robots, tasks that are trivial with a few robots can rapidly scale up to becoming near-impossible.

Charging is one example. But for their Kilobots, the Harvard researchers addressed this problem by sandwiching their robots between two metal sheets and passing a current through them.

Similarly, the robots receive their programming by having it beamed to their infrared receivers. And because these operations (charging and programming) can be done for all the robots at once, even if you increase the size of the swarm, the time required remains the same.

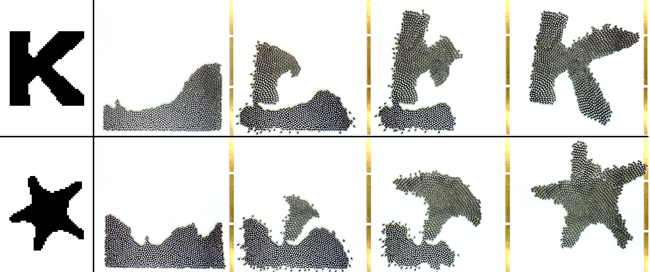

In proof of concept tests, the Harvard research team demonstrated how their Kilobots could cooperate to form large-scale shapes. These included a starfish, a wrench, and the letter K. They did this by following the same principles that govern large schools of fish, bees, ants and other organisms that follow hive-mentality.

Kilobots, Assemble!

Basically, the robots start to move around the perimeter of the swarm until they detect that they've entered the area where the shape will be formed. Then, each robot continues to move around the edge of whatever other robots are already in the shape until it detects that it's about to exit the shape, or until it bumps into the previous robot.

To do this, the Kilobots rely on an algorithm based on a simple set of capabilities: Edge-following, where a robot can move along the edge of a group by measuring distances from robots on the edge; Gradient formation, where a source robot can generate a gradient value message that increments as it propagates through the swarm, giving each robot a geodesic distance from the source; and Localization, where the robots can form a local coordinate system using communication with, and measured distances to, neighbors

Of these capabilities, the localization is both the trickiest and most important. The robots talk to each other by bouncing infrared light off of the surface that they operate on. They can tell how far away they are from other robots by measuring how much the brightness of the infrared light changes: the dimmer the light, the farther away they are. But they have no information about where exactly the light is coming from.

So, to localize, they depend on an initial "seed" group of robots to define the origin of a coordinate system, and then subsequent robots can localize based on the relative brightness of the infrared pulses coming from at least three other robots that have already been localized.

Describing their Kilobots behavior in the paper published in Science, the research team were certain to point to nature as the key inspiration. For example, the paper opens with the following quote: "In nature, groups of thousands, millions, or trillions of individual elements can self-assemble into a wide variety of forms, purely through local interaction."

Similarly, it ends by outlining the possible applications for swarm robotics in the future: "This motivates new investigations into advanced collective algorithms capable of detecting malfunctioning robots and recovering from large-scale external damages, as well as new robot designs that, like army ants, can physically attach to each other to form stable self-assemblages."

Origami-Inspired Paper Robots

Shortly before the Kilobot's made their presentation, researchers at Harvard and MIT announced the creation of a new type of reconfigurable paper robots. Here, researchers borrowed from the ancient Japanese art of origami, and perhaps a bit of from the Transformers franchise, to create their self-assembling, paper robot concept.

After the installation of tiny batteries and motors, the paper robot rises on four stumpy legs, begins to walk about in a jerky manner, but eventually can move with almost dance-like fluidity - a process that takes about four minutes. The robots, which the researchers did not name, are about 15 centimeters long, 15 centimeters wide, about five centimeters tall, and weigh less than 85 grams. They move about five centimeters per second.

The robots themselves start out a bit smaller than a normal sheet of paper, and cost about $100 to assemble for the paper, plastic, and off-the-shelf batteries and motors that are embedded and power the transformation. According to Felton, this represents a significant reduction in cost from the early machines they made which, along with the equipment needed to build them, cost just under $1,000 apiece.

And while the invention might seem like little more than an expensive children's toy to the casual observer, it would represent a step towards a new breed of tailor-made machines that can transform to carry out different functions. And as you can see from the video below, the process is quite cool to behold:

Self-Assembling Robots for Daily Needs

Felton and study co-author Daniela Rus of MIT say they see a time when someone who wants a dog-walking robot would go to a store that has specialized equipment and assemble the device themselves.

"In principle it will be possible to say, 'I want a robot to play chess with me,' and generate a machine that has the computational abilities to play chess with you," Rus said.

Today it costs a lot of money to build a robot, but this method is fast, cheap and specialized, Rus said. And eventually, the technology could produce more complex machines.

"This is a simple, flexible and rapid design process and a step toward the dream of realizing the vision of 24-hour robot manufacturing," Rus said.

Once they assemble themselves automatically with heat-activated hinges that allow the folding, there are no more changes, Rus and Felton said. Robotics pioneer Rodney Brooks, an MIT emeritus professor who wasn't part of the research, said this could be close to other momentous changes in technology, such as the first 3D printers or even 1947's ENIAC early computer.

"Lots more people will join in working on these techniques, each making incremental progress and decades from now we'll wonder why it took so long to get where we'll then be with it," Brooks said in an email.

This small lightweight type of robot could explore outer space and other dangerous environments, and get into cramped places for search-and-rescue missions, researchers said. But that's just the start of what may be a long-envisioned robotic revolution. This eventually could be as technology-changing as the three-dimensional printer, said experts unconnected with the study and Harvard robotics researcher Sam Felton, who is lead author of the paper published in August in the journal Science.

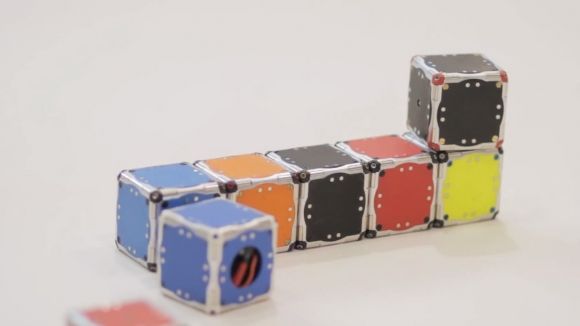

In addition, last May, researchers at the the Biorobotics Laboratory (BioRob) at École Polytechnique Fédérale de Lausanne (EPFL) unveiled a new system of self-assembling robots for household use. Known as Roombots, these robots are essentially reconfigurable modules that connect to each other to change shape and transform into different types of furniture, based on the needs and specifications of users.

Like LEGO bricks, Roombots can be stacked upon each other to create various structures and/or combined with furniture and other objects, changing not only their shape, but also and functionality. For instance, a person lying down on a Roombot bed could slowly be moved into a seated position, or a table could scoot over to a corner or tilt itself to help a book slide into a person's hands.

The team has solved a number of significant milestones, such as the having the Roombots move freely, to bring all this multi-functionality closer. Each 22 cm-long module (which is made up of four half-spheres) has a wireless connection, a battery, and three motors that allow the module to pivot with three degrees of freedom. Each modules also has retractable “claws” that are used to attach to other pieces to form larger structures.

With a series of rotations and connections, the modules can change shape and become any of a variety of objects. A special surface with holes adapted to the Roombots’ mechanical claws can also allow the modules to anchor to a wall or floor.

The Roombots can even climb up a wall or over a step, when the surface is outfitted with connector plates. They're are also capable of picking up connector plates and arranging them to form, say, a table's surface. Massimo Vespignani, a PhD student at BioRob, explained the purpose of this design and the advantages in a recent interview with Gizmag:

"We start from a group of Roombot modules that might be stacked together for storage. The modules detach from this pile to form structures of two or more modules. At this point they can start moving around the room in what we call off-grid locomotion...

A single module can autonomously reach any position on a plane (this being on the floor, walls, or ceiling), and overcome a concave edge. In order to go over convex edges two modules need to collaborate...

The advantage would be that the modules can be tightly packed together for transportation and then can reconfigure into any type of structure (for example a robotic manipulator)...

We can 'augment' existing furniture by placing compatible connectors on it and attaching Roombots modules to allow it to move around the house."

The EPFL team's main goal was to create self-assembling interactive furniture that could suit the needs of disabled or elderly persons by morphing into different configuration. However, the range of applications for these kind of robotics is virtually infinite. For example, as seen in the video below, a series of Roombots as feet on a table that not only let it move around the room and come to the owner, but adjust its height as well.

Auke Ijspeert, head of the Biorob, envisions that this type of customization could be used for physically challenged people who could greatly benefit from furniture that adapts to their needs and movements. As he said in a recent statement:

"It could be very useful for disabled individuals to be able to ask objects to come closer to them, or to move out of the way. [They could also be used as] 'Lego blocks' [for makers to] find their own function and applications."

MIT's M-Blocks Self-Assembling Robot

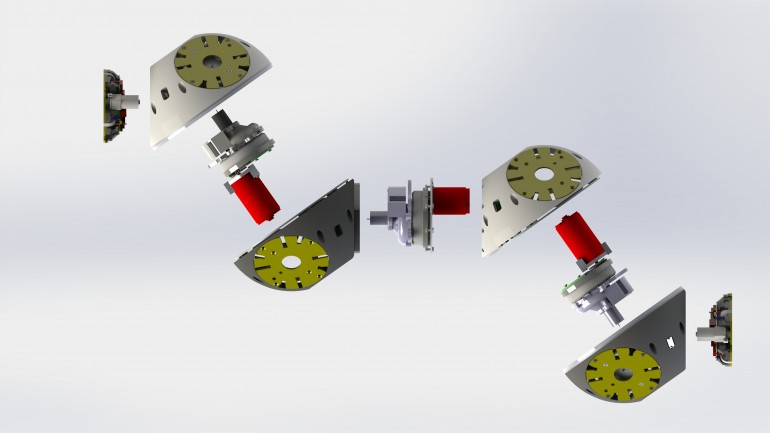

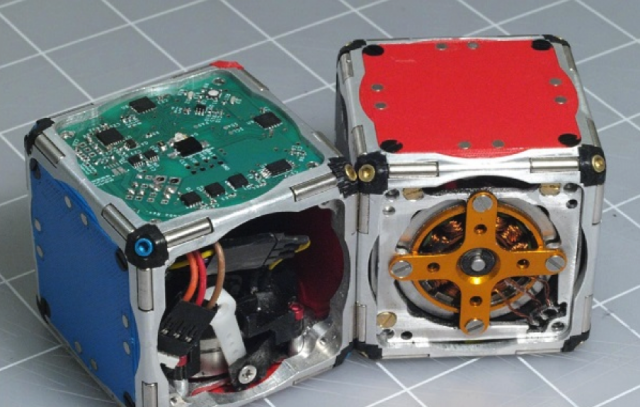

And then there is MIT's more complex self-assembling robotic system known as M-Blocks - which are programmable cube robots with no external moving parts.

Created by research scientist John Romanishin of MIT’s Computer Science and Artificial Intelligence Laboratory (CSAIL), these robots can climb over and around each other, leap through air, roll across the ground, snap together into different shapes, and even move while suspended upside down from metallic surfaces.

The key behind making the M-blocks work is a flywheel that can reach speeds of 20,000 revolutions per minute placed at their core. When the flywheel is braked, it imparts its angular momentum to the cube. And on each edge of an M-Block and on every face are permanent magnets that allow any two cubes to attach to each other.

To compensate for its static instability, the cubes also have two cylindrical magnets mounted like rolling pins on each edge. When two cubes approach each other, the magnets naturally rotate so that north poles align with south, and vice versa. Any face of any cube can thus attach to any face of any other.

The cubes’ edges are also beveled, so when two cubes are face to face, there’s a slight gap between their magnets. When one cube begins to flip on top of another, the bevels, and thus the magnets, touch. The connection between the cubes becomes much stronger, anchoring the pivot. On each face of a cube are four more pairs of smaller magnets, arranged symmetrically, which help snap a moving cube into place when it lands on top of another.

The MIT researchers are currently building an army of 100 cubes, each of which can move in any direction, and designing algorithms to guide them. “We want hundreds of cubes, scattered randomly across the floor, to be able to identify each other, coalesce, and autonomously transform into a chair, or a ladder, or a desk, on demand,” Romanishin says.

Romanishin, robotics professor Daniela Rus, and postdoc Kyle Gilpin also presented a paper describing their new robots at the IEEE/RSJ International Conference on Intelligent Robots and Systems that took place in Japan earlier this month.

The Numerous Other Benefits of Self-Assembling Robots

Once again, the possibilities presented by this proof-of-concept are staggering. Armies of these mobile cubes could temporarily repair bridges or buildings during emergencies. These cubes could assemble into different types of furniture or heavy equipment as needed. And they could swarm into environments hostile or inaccessible to humans, diagnose problems, and then reorganize themselves to provide solutions.

They could even be special-purpose cubes: containing cameras, or lights, or battery packs, or other equipment that the mobile cubes could transport. For more info, check out the demo video:

Taken together, these developments represent a major step in the direction of self-assembling robots that are capable of taking on just about any task. These range from maintaining and repairs infrastructure, to constructing buildings quickly and efficiently. They could also be sent into space (as already mentioned) to conduct large-scale research missions, compiling terabytes (or petabytes) of data from thousands of units and beaming it back to Earth.

But the ultimate goal is robots that can build other robots. And not in the factory-model way, but in the "swarms of self-replicated robots" way that has been popularized by science fiction. This idea, which is part of the larger vision of smart matter and nanotechnology, promises a futuristic where the very building blocks of everyday objects as programmable, reconfiguring materials that can shape or properties as needed.

In such a world, swarms (or fogs) of tiny robotics could be capable of performing any task - from turning carbon dust into diamonds and lead into gold - but also repairing, maintaining and reproducing themselves, making just about anything possible.

If you're interesting in making such a vision come true, be sure to check out HeroX's Self-Replicating Robot Challenge.

And be sure to check out this video from Harvard University showing the Kilobots in action:

Sources:

- www.instructables.com/id/Autonomous,-Self-Assembling-Robots/

- www.cbc.ca/news/technology/real-transformers-self-assembling-paper-robots-invented-1.2730551

- www.extremetech.com/extreme/187736-harvard-mit-create-first-self-assembling-robots-the-first-real-transformers

- mobots.epfl.ch/self-assembling-robots.html

- www.sciencemag.org/content/345/6198/795

- www.seas.harvard.edu/news/2014/08/self-organizing-thousand-robot-swarm

- techcrunch.com/2014/08/14/watch-a-thousand-micro-robots-self-assemble-into-wild-shapes/

- www.gizmag.com/roombot-robots-reconfigurable-furniture/32211/

- www.kurzweilai.net/mit-inventor-unleashes-hundreds-of-self-assembling-cube-swarmbots

- spectrum.ieee.org/automaton/robotics/robotics-hardware/a-thousand-kilobots-self-assemble

Image Credits:

- Kilobots: Harvard University/ Mike Rubenstein/Science/AAAS

- Paper-transformer robots: Seth Kroll/Wyss Institute/Science/Associated Press

- Roombots: EPFL/BioRob

- M-blocks: MIT/CSAIL/M. Scott Brauer