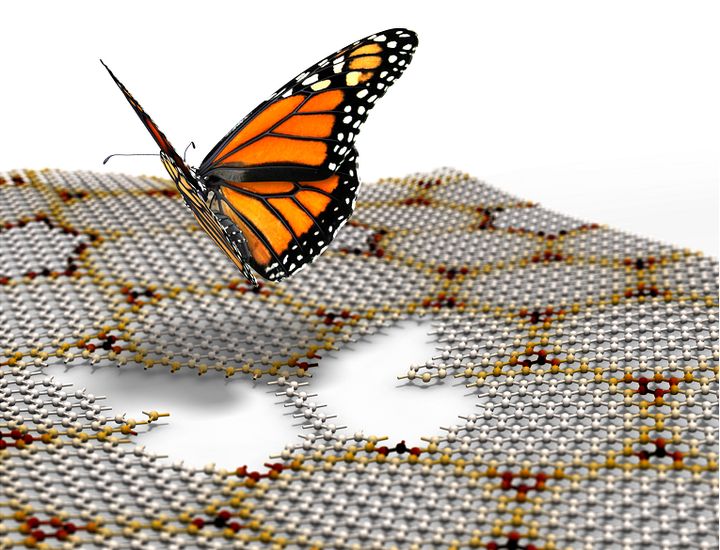

What Is Graphene?

Since it was first discovered in 2003, research into the miracle material known as graphene has expanded rapidly. Composed purely of carbon atoms arranged in hexagonal configurations one atom thick, the material is known for its ability to conduct heat and electricity with great efficiency. Because of this, researchers have been exploring the possibility of using it in the fields of electronics, energy storage, photovoltaic cells, biological engineering and even medical treatment.

Graphene Uses For Body Armor

However, little research had been done into the materials ability to absorb impacts. If there’s one thing graphene is known for, other than its conductivity, it is its sheer strength. Despite its low weight, the material is remarkably strong and durable, even more so than steel or Kevlar. Little wonder then why researchers are considering using it to create new forms of body armor.

Until recently, research into graphene’s has focused on its tensile strength - how much stress it can withstand when being pulled taught. With 200 times the strength of steel, it is being consideredfor the construction of concepts like the space elevator. But almost as impressive is the fact that it can dissipate 10 times the amount of kinetic energy as steel, which means it is also very strong in the face of direct assault.

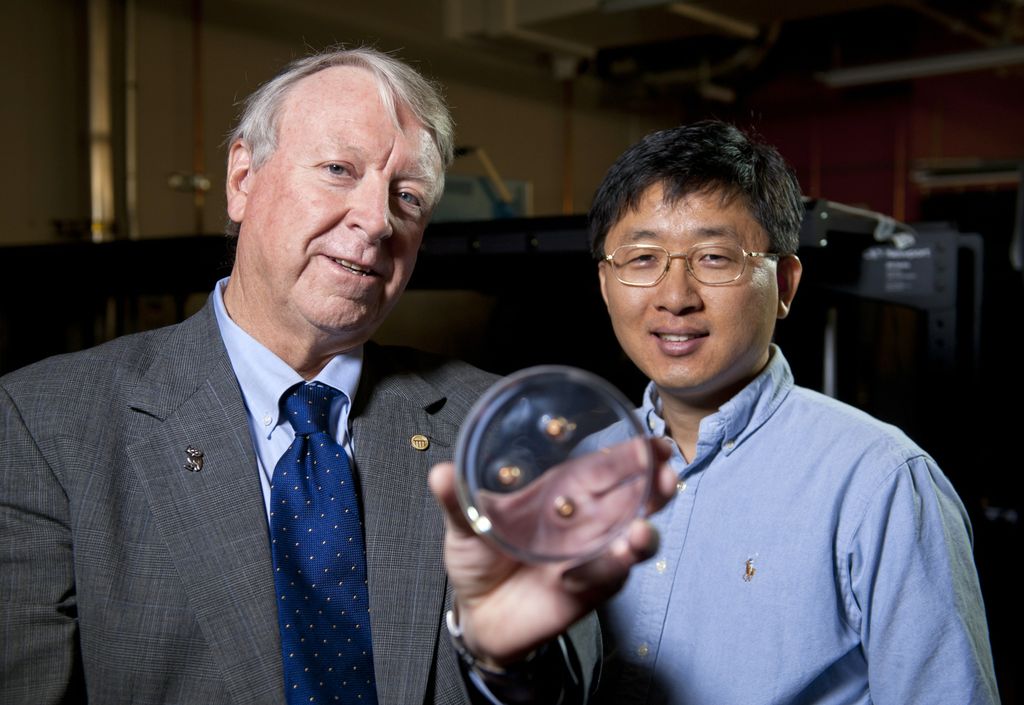

This research into the potential of graphene for use as body-armor comes to us from Rice University, Houston, with additional support being provided by the Defense Threat Reduction Agency and the Welch Foundation - a Texas-based non-profit organization dedicated to the funding of chemistry research.

At Rice, materials scientist Edwin Thomas and assistant professor Jae-Hwang Lee of the University of Massachusetts, Amherst, created an impact test using small sheets of graphene, and subjected them to a process known as the laser-induced projectile impact test (LIPIT).

Graphene Technology For Body Armor

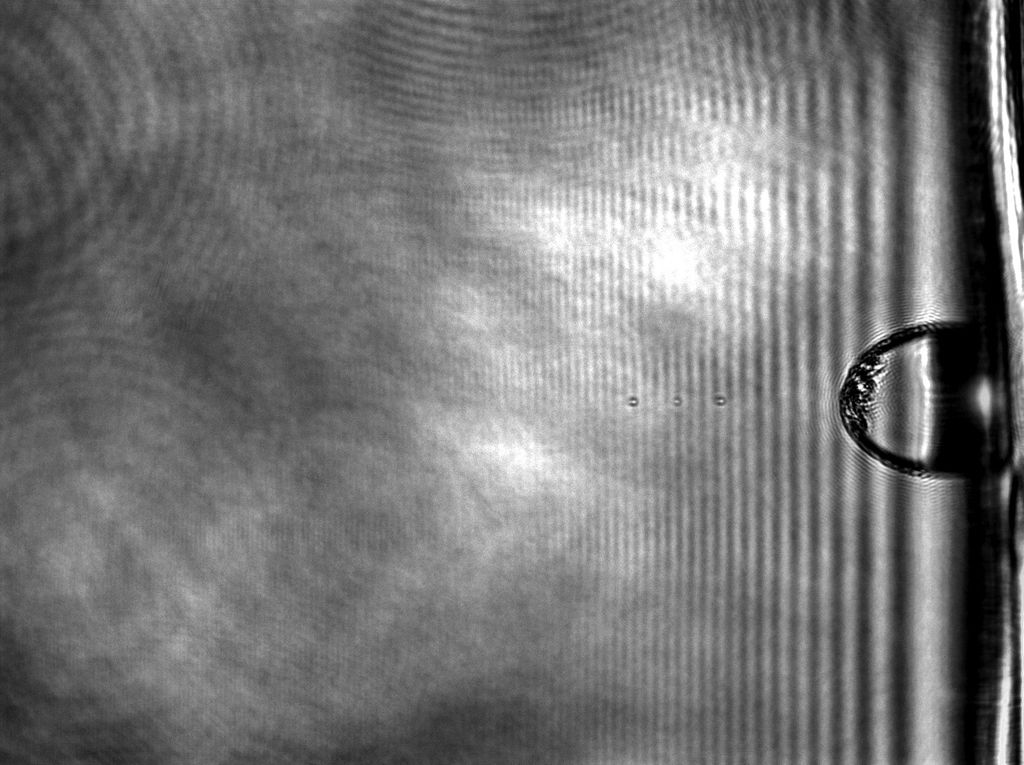

This process, which was pioneered by Rice labs, works by driving small spheres away from the opposite side of an absorbing gold surface at great speed. Using this laser-driven process, they were able to send “microbullets” against graphene sheets at speeds of up 3 km (1.9 miles) per second, which is much faster than the velocity of bullets being fired from a AK-47 assault rifle.

For the sake of the test, the research team lined up multilayer graphene sheets that were derived from bulk graphite – ranging from 10 to 100 nanometers in thickness. They then used a high-speed camera to capture images of the projectiles before and after they impacted the sheets hits, ans then finished by using microscopic images to assess the damage caused.

In each case, the microbullets punctured the graphene, but did not leave a clean, tidy hole. Instead, they noted the presence of fracture patterns around each point of impact, indicating that the graphene stretched before breaking. From their observations, they were able to calculate the amount of energy absorbed by the material and the rate at which it was able to dissipate it.

Graphene Strength Testing

They concluded that the graphene distributed the stress of the bullets over a wide area at speeds of up to 2200 meters (7217 feet) per second. This is not only a rate of stress transfer higher than with any known material, it is also faster than the speed of sound in air - which is equivalent to 342 meters (1,125 feet) per second.

What they found was that graphene's ability to simultaneously be stiff, strong and elastic makes it ideal for protective shielding. As Professor Thomas explained to Rice University's news and media oulet: "The game in protection is getting the stress to distribute over a large area. It's a race. If the cone can move out at an appreciable velocity compared with the velocity of the projectile, the stress isn't localized beneath the projectile."

What this means is that a vest that is augmented with sheets of graphene would not only have a better chance of stopping a bullet, it would also be able to distribute the stress outward much more effectively. This would have the effect of reducing deaths and injuries associated with "blunt trauma", which in the case of gunshots is almost as lethal as a bullet wound itself.

Graphene Applications For Military and Aircraft

In addition, the ability of graphene layers to dissipate stress could also be useful with tanks and armored vehicles considering that kinetic weapons - like depleted uranium flechets and high-energy directed explosive devices - are widely used against them. Already, blocks of "reactive armor" and segments of composite are placed over tanks to offer additional protection, so it is not difficult to image that these existing systems could be further supplemented with graphene layers.

And last, but not least, graphene could provide lightweight shielding for spacecraft and high-altitude supersonic (and hypersonic) aircraft. The combination of efficient heat and energy transfer would make it ideal when layered with other composites to ensure craft flying through Earth's and other planet's atmospheres don't burn up.

Naturally, this is hardly the only field of research where graphene is offering new and exciting possibilities. And as with electronics, health sciences, medicine and energy, the potential is mind-boggling. One can imagine with little effort a new generation of super-strong flak vests, military vehicles and spacecraft, all augmented by the addition of tiny sheets of incredibly light material.

Graphene Body Armor Usage

And considering its use in biological research, it is entirely possible that a form of implantable graphene could also be developed for soldiers and bodyguards, people who wear their armor under their skin instead of over their bodies. It's even conceivable that graphene layers could be placed on bones to fortify them against attack and prevent them from breaking. Move over adamantium, graphene is in town!

Prof. Thomas and Assistant Professor Jae-Hwang Lee's research report appeared in the December edition of Science Magazine, titled "Microbullet hits confirm graphene’s strength". The paper’s co-authors are Rice graduate student Phillip Loya and Jun Lou, an associate professor of materialscience and nanoengineering.

And be sure to check out this video from Rice University showing the microbullet testing:

Sources:

- www.sciencemag.org/content/346/6213/1092.short

- www.gizmag.com/graphene-bulletproof-armor/35004/

- news.rice.edu/2014/12/01/microbullet-hits-confirm-graphenes-strength/

- www.graphene.manchester.ac.uk/explore/the-story-of-graphene/

- www.graphene.manchester.ac.uk/discover/graphene-week-2015/

- www.engadget.com/2014/11/28/graphene-stronger-than-kevlar-when-blasted-with-mach-9-microbull/

- www.extremetech.com/extreme/195089-graphene-body-armor-twice-the-stopping-power-of-kevlar-at-a-fraction-of-the-weight

Image Credits:

- Top Image: graphene.manchester.ac.uk

- Prof. Thomas and Assistant Prof. Jae-Hwang Lee: news.rice.edu

- Graphene microbullet test: news.rice.edu

- Tank: guns-pictures.drippic.com

The researchers built a custom stage to line up multilayer graphene sheets mechanically drawn from bulk graphite. They tested sheets ranging from 10 to 100 nanometers thick (up to 300 graphene layers). They then used a high-speed camera to capture images of the projectiles before and after hits to judge their speed and viewed microscope images of the damage to the sheets. - See more at: http://news.rice.edu/2014/12/01/microbullet-hits-confirm-graphenes-strength/#sthash.MA1oPd9B.dpuf