The speed at which additive manufacturing (aka. 3D printing) has been progressing in the past few years is impressive and undeniable. Not only are the devices improving in terms of how fast they can generate objects (leading to a sort of Moore's Law for 3D printers), but the range of applications keeps growing all the time. And all the while, the price tag for individual, high-end printers is dropping at a staggering rate.

And yet, there are still serious limits on what the technology can do, one of the greatest having to do with scale. In short, 3D printers can only print objects that are small enough to fit within their printer tray. However, if someone wants to create a large-scale object, they are either forced to find a printer large enough to accommodate the job, or assemble it seperately as a series of modular components and then snap them together.

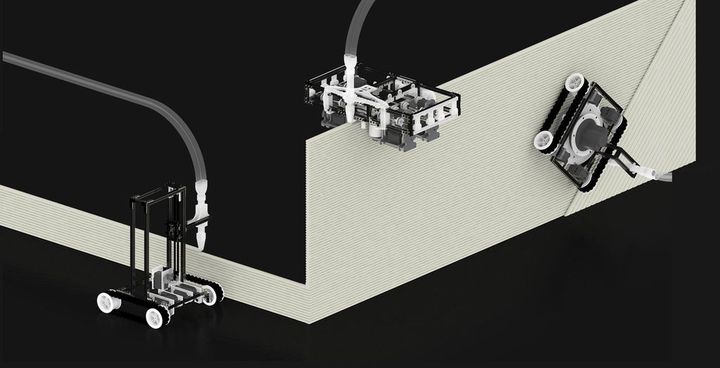

However, new ideas are emerging all the time that could usher in an age of free-form, large-scale assembly. And that's where Minibuilders come in, a new series of mobile 3D printer robots that can assemble large structures on site. Developed by Petr Novikov, Saša Jokić, and a team of designers from the Institute for Advanced Architecture of Catalonia (IAAC) in Barcelona, Spain, the Minibuilder concept offers the possibility of freely printing 3D structures that are far larger than the printers themselves.

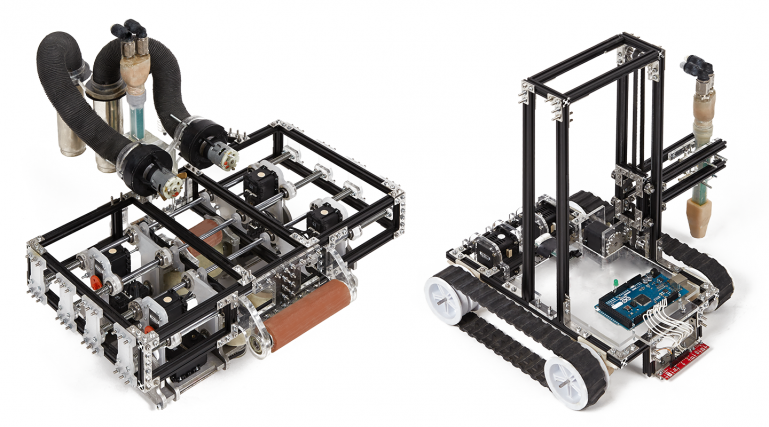

The Gripper (left) and Foundation (right) robots, two of the three Minibuilders robots. Credit: iaac.net

Though other 3D printed structures have been created in the past - such as the low-cost housing in China, where 10 houses were printed using recycled materials in less than 24 hours - they were all produced in sections off-site, which then had to be transported and assembled. In contrast, the Minibuilders are able to print structures in one continuous process on-site - starting from the ground and working up, layer by layer.

Working in teams of three and carrying out different functions, the robots work independently on their own task, but in coordination with each other on the overall structure. Each Minibuilder performs its role in order, using instructions provided by a central computer in conjunction with its own sensors and local positioning systems. In addition to working in teams of three, they come in three classes,

First, there is the Foundation Robot, which measures 35 cm in length, 37 cm in height, and 26 cm in width. These robots use tracks to move around and a line-follower sensor to position themselves and recognize curves on the ground. They also comes with a linear actuator so they can position their nozzles relative to the height of a printed layer and thereby put down the foundation of the structure.

The demonstration building being assembled outside of the Design Museum of Barcelona. Credit: iaac.net

Then there is the Grip Robot, which attaches itself to the structure by clamping onto it with its 4 rollers. Each of these rollers is connected to a steering actuator that allows the robot to position itself precisely over the structure. This robot measures 40x42x30 cm, giving it a wider base so that its nozzle can be moved sideways with a greater degree, and giving it more control over the printed shape. It also comes with a heater so it can speed up the time needed for the material to cure.

And last, there is the Vacuum Robot, a squat machine measuring 27x30x12 cm that is responsible for reinforcing the shell printed by the first two robots. Equipped with tracks, this robot also relies on a vacuum generator and a suction cup to hold onto the surface while still being able to actively move around on it. While working, these robots are attached to a "Supplier" robot that provides the liquid building material to them as required.

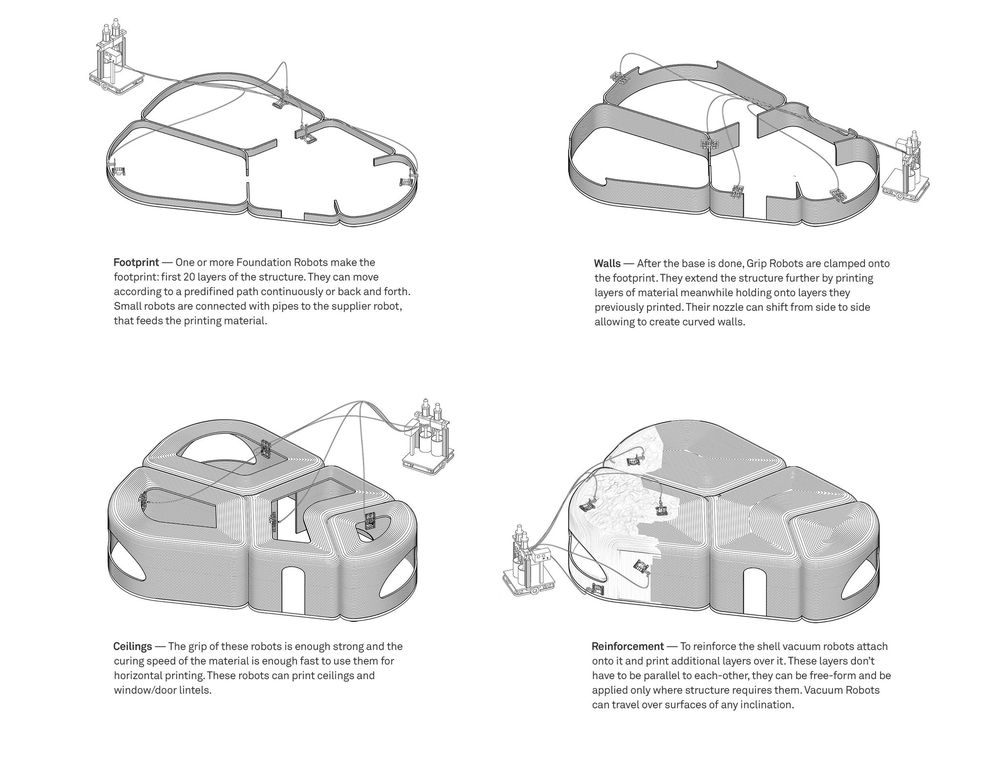

Working in groups of three, the Minibuilder robots generate structures in four phases. In phase one, also known as the "Footprint" stage, one or more Foundation Robots lay the first 20 layers of the structure. After the base is done, Grip Robots commence phase two, otherwise known as the "Walls" phase.

Artist's rendering of the four phases of the Minibuilder construction process. Credit: monograph.io

During this phase, Grip Robots clamp onto the Footprint using their four rollers and extend the structure by printing layer after layer of material on top of the base. They then move their way around the structure, laying down additional material to extend the walls and using their heaters to dry it. Their nozzles can also shift from side to side, allowing for the creation of curved walls.

In phase three, known as "Ceilings", Grip Robots begin laying down the horizontal layers to create the ceiling, windows and doorframes. In the final phase, known as "Reinforcement", the Vacuum Robots attach themselves to the printed shell, printing material at an almost perpendicular angle to the other layers, thus providing strength and reinforcement to the overall structure.

The first construction project completed by the Minibuilders was a demonstration piece created in the exterior exhibition space of the Design Museum of Barcelona (video below). While the structure itself was humble compared to what the inventors have planned, it nevertheless demonstrated how 3D printing robots can fabricate structures many times their own size.

In addition, this is not the first time that Novikov and Jokić have worked towards the creation of a free-form 3D printer. Last year, as part of an internship at Amsterdam’s Joris Laarman Lab, they worked to research, design, and patent a new method for 3-D printing called Mataerial. This printer design relies on two liquid polymers which, when combined, harden to form solid plastic - a process they refer to as "Anti-Gravity Object Modeling,"

In addition to being able to print objects in three dimensions without the need of a printer box, the technology behind Mataerial is also impressive because of its scalability. Essentially, it can be scaled up or down to print objects that are either narrower than 1 mm, or as big as a professional 3D printer, which would be a boon for furniture design or architectural construction.

Also, in recent years both the ESA and NASA's Jet Propulsion Laboratory announced that they were exploring the idea of using 3D printing technology to construct a Moon Base. Relying on a technique known as "sintering" - where microwaves are used to bombard regolith (aka. Moon dust) and turn it into molten ceramic - a series of robots with specialized nozzles would be able to assemble structures on-site near the Moon's South Pole using nothing but local materials.

It's been the stuff of fevered sci-fi predictions for decades: teams of small robots that are able to move about independently and manufacture large-scale objects. And while these dreams generally involve nanomachines assembling objects at the microscopic or atomic level, no one can deny that in its current form, the technology for 3D printing robots is sound and the potential vast.

At the rate things are going, it would not be farfetched at all to envision small swarms of robots assembling everything from houses to apartment blocks in a few years' time. And in the meantime, be sure to enjoy this video of the Minibuilders in action at the Design Museum of Barcelona:

Top image: iaac.net

- iaac.net/printingrobots/

- www.mataerial.com/

- www.a-etc.net/sinterhab/

- monograph.io/iaac/minibuilders

- 3dprint.com/6340/minibuilders-3d-print-robots/

- www.gizmag.com/china-winsun-3d-printed-house/31757/

- inhabitat.com/minibuilders-family-of-tiny-robots-3d-print-giant-buildings-on-site/

- www.gizmag.com/minibuilder-robots-3d-print-large-scale-structures/32573/

- www.cnet.com/news/minibuilders-an-experiment-in-builder-bots/

- www.fastcoexist.com/1682148/this-anti-gravity-3-d-printer-can-make-objects-anywhere-even-space

- www.wired.co.uk/news/archive/2013-03/01/giant-nasa-spider-moon-base-sinterhab

- www.gizmag.com/esa-moon-moonbase-3d-printing/34673/

- 3dprint.com/794/3d-printing-of-moon-base-new-technology-and-ideas-make-it-soon-possible/