For decades, the price of manufacturing and installing solar cells has been steadily dropping. In fact, in accordance with what is known as Swanson's Law, the price of solar has been cut in half with every passing decade. Whereas the cost per watt of solar power was $76.67 back in 1977; last year, it had reached a meager 36 cents.

Much of this has to do with the upsurge in the mass production of solar cells in India and China in recent years. As the world's two fastest-growing economies, their adoption and production of the technology has helped to drive down prices. But at the same time, credit must also be given to the extensive research that has boosted solar cell efficiency and produced newer, low-cost production technologies.

In this respect, flexible, organic solar cells have long been the subject of great interest. Relying on organic polymers or small organic molecules to achieve a photovoltaic reaction, these types of solar cells offer two major benefits. For one, they only need a small amount of material to convert photons into electrons, and they can also be manufactured in large quantities using what is called roll-to-roll (R2R) processing - a technique in which materials are printed in the same way newspapers are.

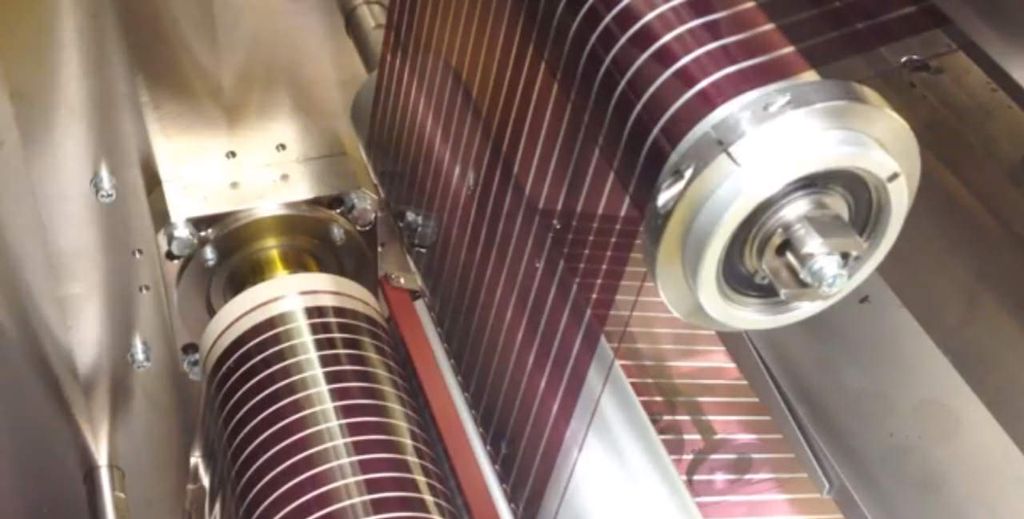

Solar cells that can be printed using the roll-to-roll (R2R) method will mean significantly cheaper solar technology. Credit: popupcity.net

However, such solar cells also present a challenge, seeing as how everything about them - from the transparent electrodes, to barrier layers and even the entire device itself - has to be flexible in order to be produced this way. Such has been the goal of the EU-funded project known as "TREASORES" (Transparent Electrodes for Large Area Large Scale Production of Organic Optoelectronic Devices), an international organization that includes 19 labs and companies from five European countries.

Beginning in Nov. 2012, the purpose of this project has to been to develop and demonstrate technologies that would facilitate R2R production of organic optoelectronic devices such as solar cells and LED lighting panels. Led by Frank Nüesch of Empa - the Swiss Federal Laboratories for Materials Science and Technology - and with an overall budget of more than 14 million Euros, this international team recently reached some important developmental milestones.

For starters, the project completed its mid-term review and was able to showcase the development of an ultra-thin transparent silver electrode. Not only was these newly-developed electrodes able to outperform traditional ones made from indium tin oxide (ITO), they were also significantly cheaper to produce - owning to the fact that they were manufactured using an element which, unlike indium, is not scarce.

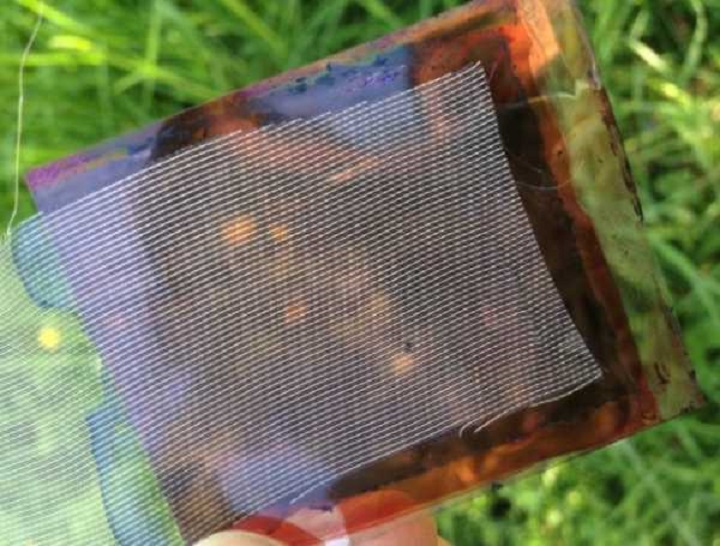

The transparent, flexible solar cells developed by the TREASORES cost less and can outperform conventional solar cells. Credit: Empa

The researchers could also demonstrate a record efficiency of 7 % for a perovskite-based solar cell using the transparent electrodes they produced. Last, but not least, through a series of field tests, they were able to demonstrate that their first fully R2R-produced solar cells have a service life that is commercially-acceptable compared to conventional solar cells.

According to Nüesch, the next step will be to scale up and improve the most promising technologies they have identified so far to produce barrier materials and transparent electrodes in larger quantities (over 100 meters in length). After that, the TREASORES project will continue to develop other promising technologies such as transparent and flexible electrodes based on woven fabrics, nanowires and carbon nanotubes (CNTs).

"We are working on the most crucial issues in large-scale organic optoelectronics," he said. "Our new low-cost electrode substrates already outperform existing conductive oxide electrodes in many ways. But we must further improve the resulting device yields from large-scale production by reducing the defect density of the substrates."

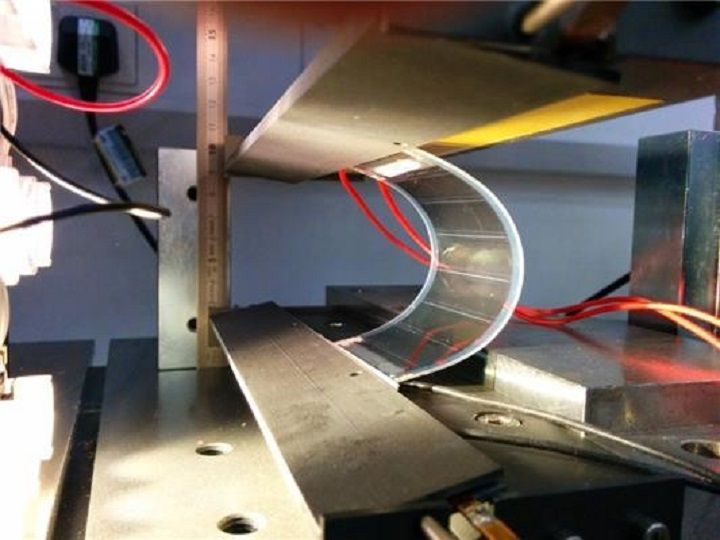

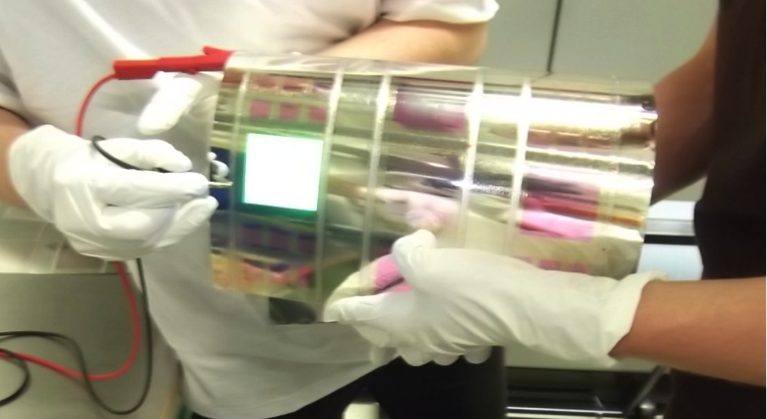

Flexible Organic Light-Emitting Diode (OLED) materials being tested by TREASORES researchers. Credit: treasores.eu

Naturally, there are concerns about the efficiency limits of such solar cells, which lag far behind traditional single-junction cells made of silicon. Typically, these cells can achieve an energy conversion efficiency rating of about 34% (in what is known as the Shockley-Queisser limit). And thanks to recent innovations using nanomaterials, different substrates, and ongoing research into improved photovoltaic technology, this limit has been surpassed.

In addition, the performance and longevity values of this new type of flexible, transparent material are not quite consistent with conventional OLED and OLEC devices. However, Nüesch stressed that "all electrodes were produced by an R2R process in an industrial environment or with industrially relevant processes on large areas of the polymer substrate. We can thus say that the processes we used are robust and reproducible."

In short, this development stands as a successful demonstration that the R2R process can be adapted to creating flexible solar cells and organic LEDs, which will invariably drive the price of the technology even lower. And with refinements and improvements made in the process, the resulting printable materials are also likely to improve in performance and efficiency, leading to more rapid adoption.

Sources: