Additive manufacturing (aka. 3-D printing) has had a revolutionary impact in recent years. From its humble beginnings, rapidly creating plastic prototypes and models for engineers and architects, 3-D printing has very quickly become a technology that offers an endless array of possibilities. With applications ranging from the creation of metal components and the printing of organic tissues to food, it seems like there is nothing that additive manufacturing can't produce.

And in their drive to incorporate the latest technologies into the ongoing pursuit of space exploration, NASA's Centennial Challenges and the National Additive Manufacturing Innovation Institute (aka. America Makes) recently came together to launch the 3-D Printed Habitat Challenge. Officially announced in May 2015, this $2.25 million competition was conceived for the purpose of designing 3-D printed habitats for the sake of deep space exploration, with an eye to the agency's planned journey to Mars.

The first phase of the competition - the Design Competition - wrapped up on Sept. 27th, 2015. For this phase, participants were called upon to develop state-of-the-art architectural concepts that incorporate 3-D printing techniques to create sustainable housing suited to the Martian environment. Over 165 submissions were made, and the participants and their designs were judged at the 2015 World Maker Faire in New York. From these, 30 were selected and awarded from a prize purse of $50,000.

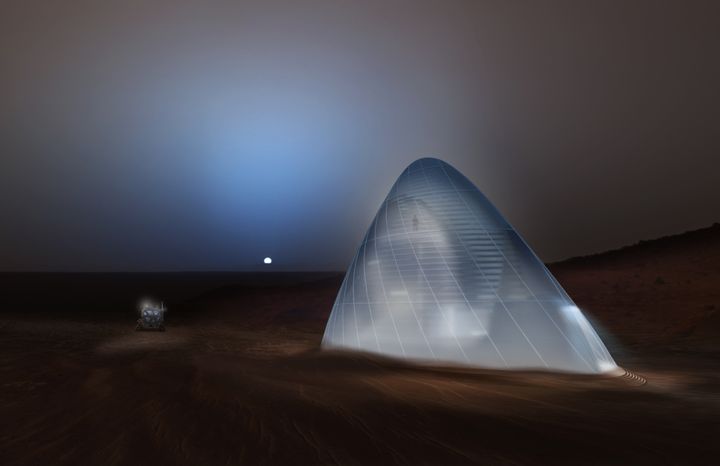

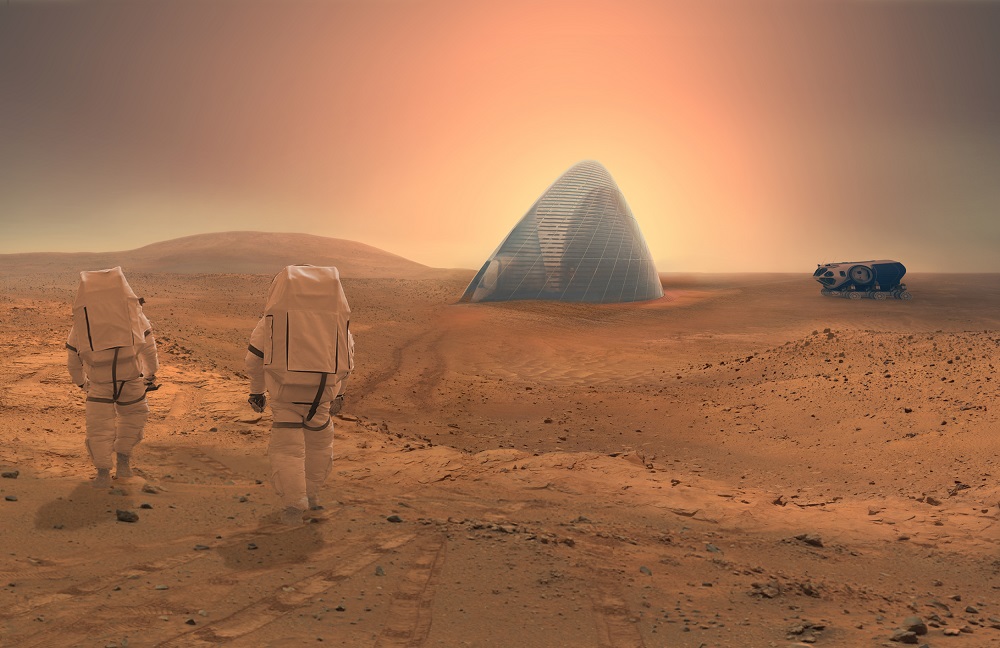

Artist's concept of the Mars Ice House, a concept which takes advantage of Mars' low temperature and the availability of water ice to create a habitat. Credit: marsicehouse.com

By the end of first phase, three winners overall were selected and awarded from an additional prize purse of $40,000. First place and a prize of $25,000 went to Team SEArch (Space Exploration Architecture)/Clouds Architecture Office for their Mars Ice House. Taking their inspiration from recent missions that have shown just how prevalent water ice is in our Solar System - especially on the surface of Mars - the Ice House relies on the abundance of water and the perennially cold temperatures in Mars’ northern latitudes to create a habitation for explorers.

Construction of the Ice House relies on two classes of robots to "print" the habitat from the ground up. First, the WaSiBo robot is dispatched to the surface, where it gathers Martian regolith and uses it to create the structure's foundation. Next, the IBo robot uses a triple nozzle to dispense a composite of water, fiber and aerogel along layered rings to create the walls of the habitat. The WaSiBo continues to support the IBo robot in this phase, mining water ice from the ground to keep it supplied.

The final product is a habitat that is insulated, translucent, and shields the inhabitants from harmful radiation. At the same time, and just as importantly, it allows its users to see the outside world, giving them the chance to establish visual connections with their environment and experience natural sunlight (rather than relying on some artificial substitute).

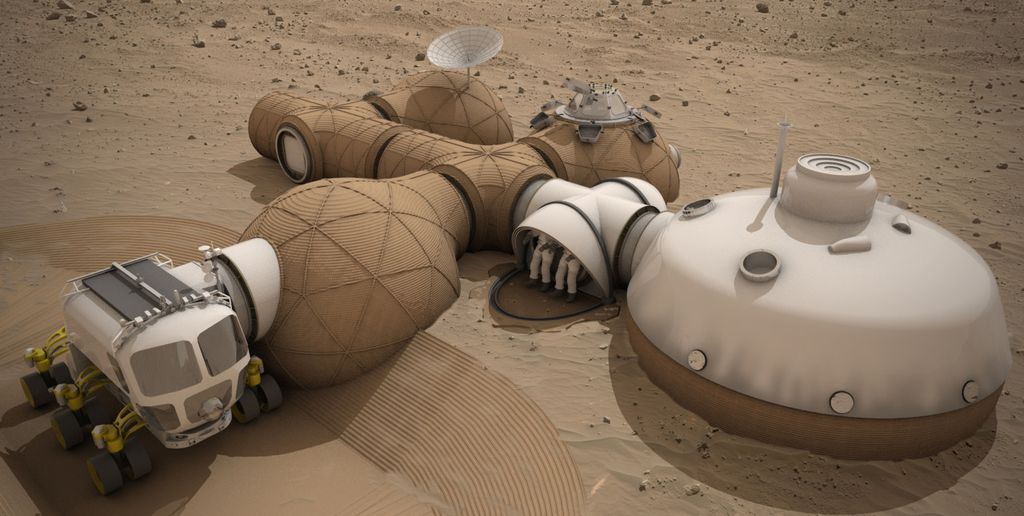

Second place, a prize of $15,000, and the People's Choice Award was given to Team Gamma for their concept of the Regolith Additive Manufacturing (RAM) system. This concept calls for the use of three inflatable dodecahedral modules to form the basic shape of the habitat. A series of semi-autonomous robots then use microwaves to melt and distribute regolith over these to form the habitat's protective outer layer. This process, known as "sintering" is also being explored by NASA and the ESA as a possible means of building bases on the Moon.

Artist's concept of Team Gamma's habitat, created using their Regolith Additive Manufacturing system. Credit: 3dpchallenge.tumblr.com

Third place was awarded to Team LavaHive for their design that calls for the use of repurposed spacecraft components and a technique known as "lava-casting" to create a Martian habitat. For this concept, the back shell of the Entry, Descent and Landing (EDL) system - that will be used to deliver the construction rovers to Mars - serves as the primary habitat's roof while an inflatable module placed underneath serves as the primary living habitat.

Two rovers will then use a combination of Martian regolith and basaltic rock to sinter and "lava-cast" ceramics that will be used to create connecting corridors and sub-habitats around the main inflatable section. The end result will then fitted, sealed internally with epoxy, and furnished into separate rooms - which could serve as living quarters, research areas, workshops, or greenhouses, depending on the nature of the mission.

All three concepts rely on a combination of in-situ resource utilization and the recycling and/or reuse of spaceship components to achieve sustainability in their design. All of this is in keeping with the core purpose of the competition, which is the creation of cost-effective modular habitats that can be built quickly and using state-of-the art manufacturing techniques so that human being can explore extra-terrestrial environments.

Artist's concept for Team LavaHive's habitat, which relies on reused spaceship parts and sintering to create a structure. Credit: 3dpchallenge.tumblr.com

Monsi Roman, the Centennial Challenges Program Manager, was very impressed with the quality of submissions the Challenge received. "The creativity and depth of the designs we’ve seen have impressed us,” he said. “These teams were not only imaginative and artistic with their entries, but they also really took into account the life-dependent functionality our future space explorers will need in an off-Earth habitat.”

Teams were judged on many factors, including architectural concept, design approach, habitability, innovation, functionality, site selection and constructability. With Phase One complete and the three winners now selected, the second phase of the competition, which consists of two levels, will now begin.

For Level 1, the Structural Member Competition, the focus will be on the fabrication technologies that would needed to create structural components from a combination of indigenous and/or recycled materials. For Level 2, the On-Site Habitat Competition, competitors will be tasked with fabricating full-scale versions of their designs using indigenous materials or indigenous materials combined with recyclables.

Leveraging new technologies and developing the means to utilize local resources are just two of the ways in which we are preparing to set foot on new worlds. As the age of space exploration continues and we begin to explore new frontiers, some very interesting concepts - be they for housing, living, working and playing in new and exotic environments - are likely to start popping up!

In the meantime, be sure to check out this video from Team SEArch/Clouds Architecture Office describing the Mars Ice House:

Do you have ideas that could help humanity explore space and distant worlds? Then head on over to the Launch a Challenge page and get ready to make it a reality!