Once thought to be the only way to obtain anything from a clothes dryer to an iPhone, the factory-to-household supply chain is no longer an impenetrable model of creating and obtaining hardware. Through simple strategies, the supply chain can be broken quite easily by any company.

1. Utilize Your Assets

The simplest way to break the supply chain is to make easy cuts within the current chain to shorten it. Many businesses are now taking it upon themselves to combine services to save costs and eliminate the middle man down the chain. Better technology makes it easier and faster to do multiple jobs. A printing company may use its own driver instead of hiring one through a broker. They may also bind their own materials instead of hiring another company. In many cases, adding one or two new jobs in the company can save hundreds of dollars that were previously spent on outsourcing, giving the company more cash as well as the freedom to work directly with consumers.

2. Change the Strategy

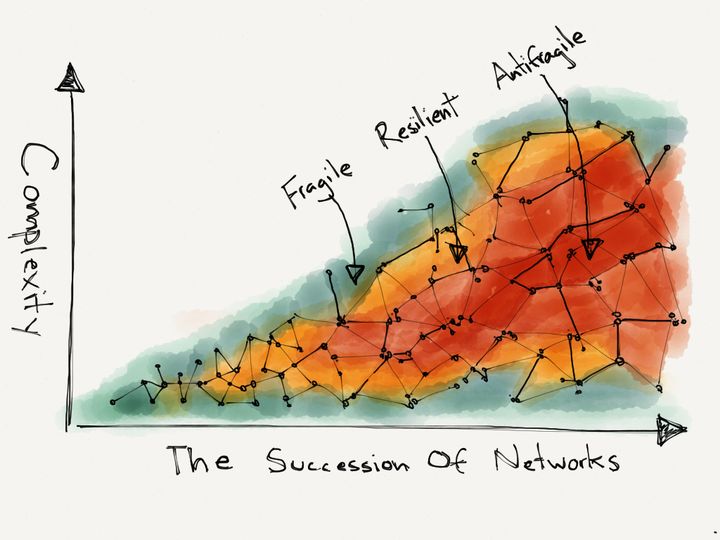

A trap that many companies fall into is the failed logic in the sentiment, “This is the way it has always been done.” Managers who are trained to operate with various expenses and extra middle-men often do not think outside the box. Breaking the supply chain can be as simple as documenting the current supply chain and analyzing it for flaws or waste. Supply chains are not static, but active components of a business that should be adapted and cut regularly. Companies that examine their supply chains and how they support the business strategy overall can eliminate unnecessary links much more easily.

3. Eliminate Waste

Much of the supply chain involves unnecessary wastes that only drive up costs and create a longer path to the customer. Many businesses have cut packaging costs to help shorten the supply chain, whether it be eliminating the boxes, bags or any extra, unnecessary packaging. Companies that recycle can cut contracts with recycling companies that charge for pick-up and instead freely recycle materials themselves. Food companies are even taking to growing their own vegetables, whether in a ground garden or on the roof, creating their own compost and even using solar energy to become more self-sustainable.

4. Cut Overhead Costs

When companies hope to drive their costs down, cutting overhead costs usually comes first. A side effect of cutting overhead costs is cutting the supply chain. Companies that cut accounting fees, supplies, rent or lawyer fees by making deals, performing their own tasks or creatively supplying their own needs in other ways can skip the lengthy supply chain that ties them to too many parties. Advertising costs, travel expenditures, phone bills and repairs are other overhead costs that can often be negotiated or completely eliminated with creative problem solving.

Shortened supply chains are also options. Businesses can partner up to provide all of each other’s missing components, eliminating the need for third, fourth and further parties to become involved in the chain. As newer, more innovative strategies are developed, it is possible that the supply chain may simply disappear in some sectors.